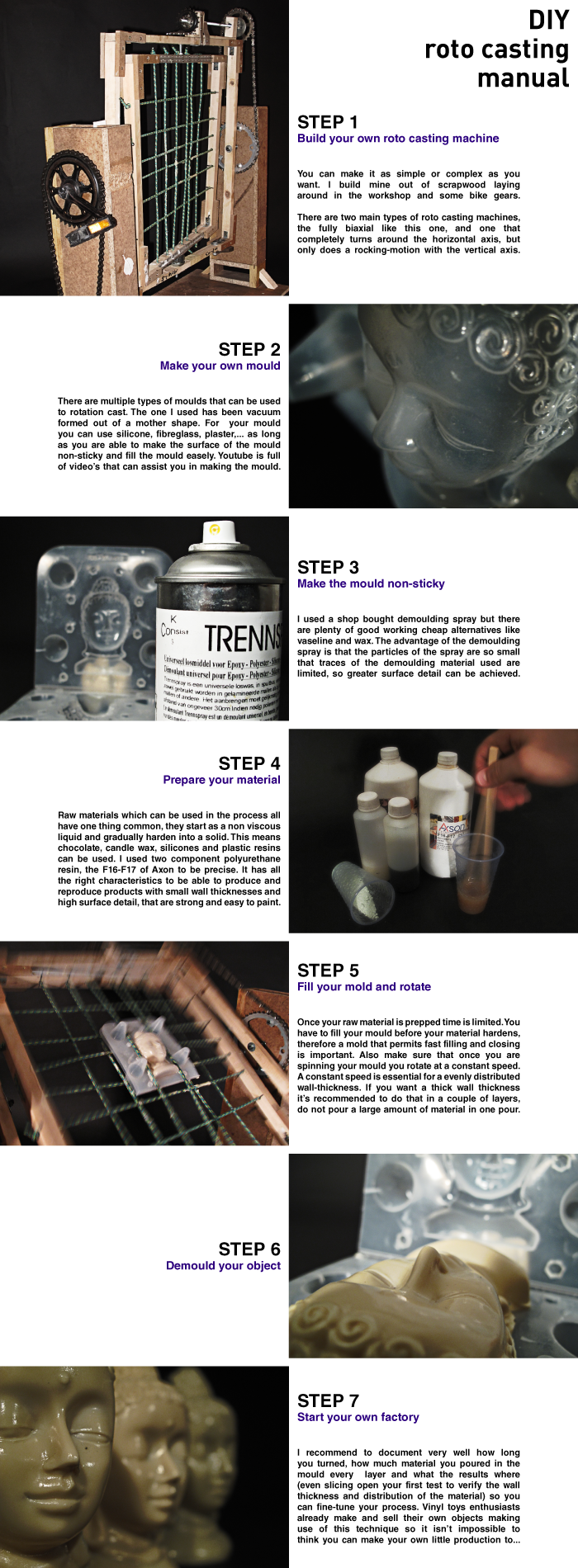

DIY Roto Casting Machine

Exploring "new" prototyping techniques | 2010

In a quest to archive many of the different prototyping techniques (from basic to more advanced) my school formulated the task to explore a specific technique for each student. I had the mission to explore rotationcasting and build myself a 'quick and dirty' but fully functional rotational casting machine.

After I was introduced to the concept of rotation casting I fell in love with the simplicity of the technique and the high resolution of the final result. Rotational casting is the little brother of rotation moulding, rotation moulding uses big machines and thermoplastics as materials used to create hollow shape's like canoes. Rotation casting can be used for smaller hollow products and materials going from resins like polyurethane to chocolate (anything that can start as a liquid and gradually hardens to a solid can be used).

In rotation casting a liquid material is poured into the mould, then the mould gets spun in a bidirectional manner so the liquid, who gradually hardens, gets evenly distributed into the internal surface of the mould. As it hardens the poured material builds layer by layer a hollow shape of the mould.

Interested in what I did one year later with this technique? Please visit this page .

The machine in action

Simple manual to try it yourself